From design to production and distribution.

Atelier Treilhard is a European industrial group, spanning several entities and partners, enabling it to control 100% of the value chain.

Our know-how, acquired over the last 70 years in jewelry and fashion, enables us to offer a unique service combining a creative spirit, industrial know-how and a European sales force, all within the same company – Atelier Treilhard.

This enables us to support brands throughout the development process, giving them the benefit of cross-functional, complementary expertise.

Thanks to La Coque de Nacre, a B2B player specializing in the jewelry sector since 1954, we integrate :

- A design office unique in France, capable of creating over 1,500 new products a year and exclusive products for various brands

- Long-standing partners capable of meeting the most demanding quality, quantity and lead-time requirements

- A catalog of over 10,000 jewelry items in gold plated, silver and steel

- A logistics center in the heart of Paris

- Multi-channel expertise

- A network of over 4,000 jewelry stores in France and Europe

- A sales force of over 20 people

And thanks to Plating Decor, a B2B player specializing in surface treatment since 1986, we integrate :

- A 1,000m² production site in Barcelona, capable of producing +20M units per year

- Unique expertise in electroplating and electrolytic treatment of precious metals

- A state-of-the-art R&D center, meeting all the technical requirements of surface treatment

- Customized finishing and packaging services

- Strong CSR production commitments

With Atelier Treilhard, you won’t have to choose between creativity, design, know-how, manufacturing and service: the multicultural dimension and diverse talents of our staff will satisfy all your needs and requirements.

We provide our customers with a complete range of services & products

The Atelier Treilhard group meets the needs of a wide variety of sectors

We design and manufacture custom metal parts, from drawing to electroplating, adapting to the requirements of each project.

Whether subcontracted or turnkey, we support the leather goods and spirits sectors with unique, refined creations.

Luxury

We work with the main players in the French and European jewelry industry, in development, industrial subcontracting and distribution, to design dedicated collections.

In addition, 4,000 independent jewelers in France and Europe select our creations, which are the fruit of the Atelier Treilhard Group’s expertise.

Jewelry

The Atelier Treilhard group puts its expertise at the service of players in the consumer goods sector, such as textiles or optics, wishing to expand their product range with accessories or jewelry. We also offer consulting and market research services to support the development of these new complementary offers.

Fashion

We offer precision electroplated metal surface treatments for both limited series and industrial volumes, for cutting-edge sectors such as automotive and aeronautics, guaranteeing consistent quality and performance.

Industry

Atelier Treilhard offers

a wide range of services

Our team is ready to support you every day

Design

Our team of designers has in-depth knowledge of the French and international jewelry markets.

Whether it's a moodboard, a technical project or detailed plans, we take care of the whole process: sketches, technical boards, 3D models.

Each creation can be legally registered with INPI.

Certification

Our RJC-certified factories guarantee responsible practices, both at production level, with strict environmental standards in line with European legislation, and at human level, with regular factory audits.

Production

Production takes place in our own factory, supplemented where necessary by carefully selected partner workshops.

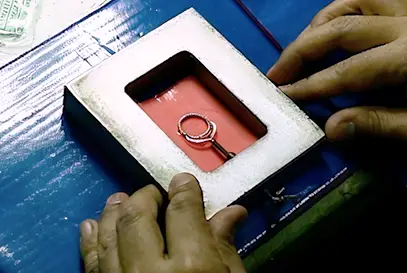

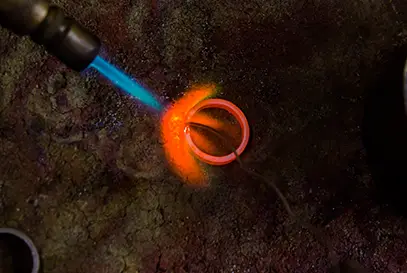

Our creations are based on a wide range of materials such as gold, vermeil, silver and steel, and can take the form of any type of jewelry thanks to our mastery of numerous manufacturing techniques, such as lost-wax casting and stamping.

Our flexible industrial process allows for production options that are 100% made in France, 100% made in Europe, or optimized with production shared between our sites in Asia and finishing in our European factory, enabling customized packaging according to requirements.

Marketing

Our graphic design studio creates eye-catching visual aids: catalogs, displays, web and print visuals. Each creation enhances the collections and supports the commercial identity of our partners, in line with market trends.

Distribution

Our logistics centers in Paris and Barcelona ensure fluid, rapid distribution throughout Europe. What's more, we offer CAM and drop-shipping solutions for simplified management.

After-Sales Services

We provide responsive after-sales service for all units produced, whether in terms of surface treatment or intrinsic part quality.

We boast an after-sales service rate of less than 2%, thanks to the regular quality controls carried out in our factories throughout the production process.

Design

Certification

Production

Our creations are based on a wide range of materials such as gold, vermeil, silver and steel, and can take the form of any type of jewelry thanks to our mastery of numerous manufacturing techniques, such as lost-wax casting and stamping.

Our flexible industrial process allows for production options that are 100% made in France, 100% made in Europe, or optimized with production shared between our sites in Asia and finishing in our European factory, enabling customized packaging according to requirements.

Marketing

Distribution

After-Sales Services

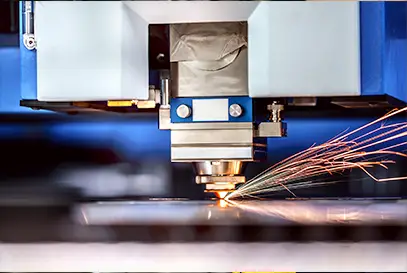

Atelier Treilhard masters a wide range of production techniques

01

Design

Jewel design using CAD software to define dimensions, shapes and technical constraints.

02

Prototyping

03

Microfusion

04

Mechanical manufacturing

05

Stamping

Stamping metal under pressure to create specific patterns or shapes.

06

Assembly

Assembly of the jewel’s various parts, by gluing, interlocking or setting.

07

Welding

08

Crimp

Securing gemstones to the jewel with claws, rails or other techniques.

09

Engraving

10

Polishing

Hand or mechanical smoothing and finishing of metal surfaces to obtain a shiny, uniform finish.

11

Electroplating

12

PVD

Metal coating or coloring technique using vacuum ionization, guaranteeing a resistant, durable but not precious finish.

13

Quality control

Meticulous verification of the jewel’s finish, dimensions and solidity before shipment.

14

Packaging

Wrapping the jewel in an appropriate case or packaging to protect it and enhance its presentation before shipment or sale.

Groupe Atelier Treilhard can help you with your creative project and its implementation.

Jewelry is a regulated profession with specific laws

Main materials

Applied in a thin layer, it hardens a surface and prevents oxidation.

Rhodium-plated Silver

Applying rhodium to silver limits oxidation and gives it a white-gold color.

Rhodium-plated metal

Rhodium can also be applied to other metals (brass, pewter, zamak) to give them a hue close to white gold.

Gold alloy ranging from 9 to 18 carats (375 to 750/000) according to international standards. The remainder of the alloy is silver and copper.

Vermeil

Sterling silver (925/1000) covered with a layer of gold. The designation is protected in certain countries (for example, in France, a minimum layer of 5 microns of gold is required, and a titration of

Gold plated

French standard requiring a hallmark. A layer of gold strictly superior to 3 microns, with a titration that can vary between 500 and 750/1000, is applied to a base of base metal, generally brass.

Golden Silver

Sterling silver (925/000) covered with a thin layer of gold, with no guarantee or specific regulations on thickness.

Golden metal

A thin layer of gold (often less than 1 micron thick) deposited on a base metal, usually brass, bronze, pewter or zamac. Titration can vary widely from 9 to 23 carats. No guarantee or specific regulations on thickness. It may be coated with a varnish (cataphoresis)..

Generally applied in thin coats to improve durability and oxidation.

Palladium-plated silver

The application of palladium on silver limits its oxidation and gives it a grey metallic hue.

Palladium-plated metal

Palladium can also be applied to other base metals (brass, bronze, pewter, zamak)

Generally applied in thin coats, it gives the product a black metallic finish.

Ruthenized silver

Applying ruthenium to silver gives it an aged or black effect.

Ruthenized metal

Ruthenium can also be applied to other metals (brass, bronze, steel, tin, zamak).

Appellation based on a silver content of 800/1000. The most common grade is 925/000, also known as sterling silver.

Silver plated

Generally applied to a base of base metal, the silver layer must be strictly greater than 10 microns (may vary by country) with a minimum grade of 925/000. This standard requires a hallmark.

Argenture

Deposition of a thin layer of silver on a metal surface. Generally used to refresh oxidized silver pieces.

A metal alloy less commonly used in jewelry, composed mainly of iron and a little carbon, chromium and other alloying elements such as nickel or manganese are added to make it stainless (“Inox”). 316L stainless steel is particularly strong and contains less nickel (REACH-compliant).

Golden steel

Not really a gold deposit (around 0.03 microns), the appellation refers to a gold color deposited by materials other than gold. This technique (PVD) does not qualify as “Fine Gold Gilding” (over 0.1 microns) or “Gold Plating” (over 3 microns).

Silvery steel

No silver deposit, the name refers to a silver color deposited by materials other than silver.

Used as a base in manufacturing processes to keep costs down.

Brass

A metal alloy often used in jewelry for its strength and flexibility. It is made of copper and zinc.

Bronze

A less common metal alloy used in jewelry, consisting mainly of copper and tin.

Zamak

Alloy essentially composed of zinc, aluminum, magnesium and copper. It is appreciated in costume jewelry for its robustness and low cost.

Brass

Soft, malleable and inexpensive metal, often used for jewelry or decorative objects. It can be worked in sheets, molded or welded, and has a silvery-gray appearance. Despite its low resistance to scratches, it remains interesting for original, inexpensive designs.

Main materials

Ranked from + to – precious, by kg

Secondary materials

Atelier Treilhard, a versatile player with a wide range of achievements

From sketch to creation

We were approached by a jewelry designer wishing to outsource her production to a group offering all the manufacturing techniques, all the quality guarantees and cultural proximity of our Paris base.

We have confidentially developed a unique and exclusive collection for her, based on her inspirations.

Manufacturing & Gilding

We were approached by a fashion brand to manufacture jewelry pieces for customizing high-end accessories.

Manufacturing, Assembly & Gilding

For a major gastronomy chain, we produced ornaments for end-of-year packaging in limited, numbered series.

Polishing & Gilding

Metal elements adorning the mroquinerie of a major luxury house.

Groupe Atelier Treilhard,

is firstly a worldwide presence

Europe

Southeast Asia

Atelier Treilhard is :

4 expertises

A single player for 4 areas of expertise: Design, Production, Finishing and Marketing

3 to 6 months

Development cycle of 3 to 6 months depending on project complexity

2%

After-sales service rate below 2%.

+ 170

Employees across Europe at your service

Commercial, social and environmental responsibility

As a real challenge for present and future generations, we are actively working to make the world a better place.

We are proud to announce our certification by the Responsible Jewellery Council (RJC) for its Code of Practices.

The RJC is a recognized international organization that promotes ethical, social and environmental standards in the HBJO industry.

Our RJC certification attests to our compliance with strict criteria in terms of human rights, environmental protection and responsible business practices.

As an industry leader, we are committed to offering high-quality products, while contributing to a more transparent and sustainable future for the jewelry industry.

We have also obtained ISO 9001 and ISO 14001 certifications, which guarantee that our processes are under control and that the environment is protected. We ensure compliance with strict requirements, with regular audits carried out by government-approved bodies.

To limit the impact of our activity on natural resources, 100% of the gold and 80% of the silver used in our products are recycled.

Because they can be melted down, all our jewelry is recyclable: gold, brass and silver can be reused.

Other projects are currently underway to reduce our environmental footprint, such as the use of 100% recyclable packaging.